- ホーム

- >

- OPIE'25

- >

- 展示会一覧

- >

- Archer OpTx, Inc.

レンズ設計・製造展 J-32

-

PerfectLensTM: Ultra-high precision molded glass asphere

Archer OpTx molded glass lenses are produced using the PerfectLensTM technology platform enabling extremely tight tolerancing with high temperature/low CTE RoHS compliant glass. The benefits to you are: unmatched optical performance, reduced labor cost for incoming inspection and production, and a more consistent final product.

-

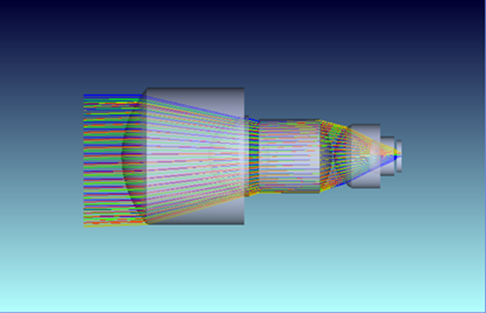

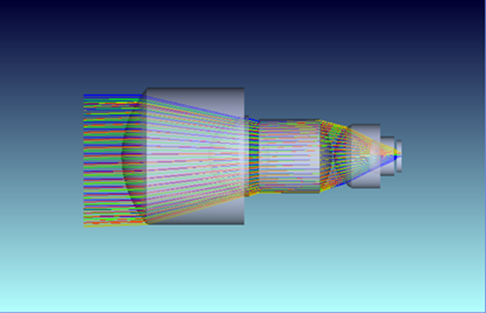

SIVA (System Imaging Vision Assembly)

Ultra-precision lens elements and mechanics allow the completed assembly to function very near the computer design model with SIVA I, II, and III. The matched resolution enables the highest quality image from your high resolution sensor. Archer OpTx offers custom SIVAs to meet your specific requirements.

-

Design Services

Archer OpTx’s in house design team can customize a lens to meet your needs. Our design team includes engineering experts in the design of optical systems, encompassing both optical, opto-mechanical, and materials science disciplines. Archer OpTx’s design team works as an integral part of your product development process, working together to develop specifications, explore different optical architectures, choosing the best solution for both performance and cost, and conducting design reviews with you at each step of the process.

-

PerfectLensTM Molded Aspheric Achromats

The first PerfectLensTM aspheric achromat that is designed to be diffraction limited from the UV through the NIR. The transmitted wavefront aberration is less than 0.06 waves PV and less than 0.01 waves RMS from 350 nm to 1550 nm. PerfectLensTM aspheric achromat is designed so the effective focal length is the same across the full spectrum; optimized for applications requiring an EFL of 2.5 mm or greater.

-

PerfectLensTM Traditional Optics

Archer OpTx provides a full range of traditional optical components with spherical, cylindrical, flat, or toroidal surfaces. Components are available in diameters of a few millimeters to support miniature cameras through two hundred millimeters for your large-scale projects. Surface accuracies are standard at Lambda/4 and can be specified to Lambda/20 if your application requires extreme precision.

-

PerfectLensTM Single Point Diamond Turned Optics

Archer OpTx's PerfectLensTM Diamond Turning offers ultra-high precision diamond turning capabilities for processing exotic materials with fast tool and 5-axis processing power. Many industries benefit from the higher precision processing of these materials.

-

PerfectLensTM Precision Machined Aspheres

Archer OpTx manufactures CNC ultra-high precision machined optics from 3 mm to 200 mm outer diameter using advanced lens element manufacturing processes to provide the opportunity for rapid prototyping. Archer OpTx can deliver a guaranteed turn around in half the time typical in the industry.

-

PerfectLensTM: Ultra-high precision molded glass asphere

Archer OpTx molded glass lenses are produced using the PerfectLensTM technology platform enabling extremely tight tolerancing with high temperature/low CTE RoHS compliant glass. The benefits to you are: unmatched optical performance, reduced labor cost for incoming inspection and production, and a more consistent final product.

-

SIVA (System Imaging Vision Assembly)

Ultra-precision lens elements and mechanics allow the completed assembly to function very near the computer design model with SIVA I, II, and III. The matched resolution enables the highest quality image from your high resolution sensor. Archer OpTx offers custom SIVAs to meet your specific requirements.

-

Design Services

Archer OpTx’s in house design team can customize a lens to meet your needs. Our design team includes engineering experts in the design of optical systems, encompassing both optical, opto-mechanical, and materials science disciplines. Archer OpTx’s design team works as an integral part of your product development process, working together to develop specifications, explore different optical architectures, choosing the best solution for both performance and cost, and conducting design reviews with you at each step of the process.

-

PerfectLensTM Molded Aspheric Achromats

The first PerfectLensTM aspheric achromat that is designed to be diffraction limited from the UV through the NIR. The transmitted wavefront aberration is less than 0.06 waves PV and less than 0.01 waves RMS from 350 nm to 1550 nm. PerfectLensTM aspheric achromat is designed so the effective focal length is the same across the full spectrum; optimized for applications requiring an EFL of 2.5 mm or greater.

-

PerfectLensTM Traditional Optics

Archer OpTx provides a full range of traditional optical components with spherical, cylindrical, flat, or toroidal surfaces. Components are available in diameters of a few millimeters to support miniature cameras through two hundred millimeters for your large-scale projects. Surface accuracies are standard at Lambda/4 and can be specified to Lambda/20 if your application requires extreme precision.

-

PerfectLensTM Single Point Diamond Turned Optics

Archer OpTx's PerfectLensTM Diamond Turning offers ultra-high precision diamond turning capabilities for processing exotic materials with fast tool and 5-axis processing power. Many industries benefit from the higher precision processing of these materials.

-

PerfectLensTM Precision Machined Aspheres

Archer OpTx manufactures CNC ultra-high precision machined optics from 3 mm to 200 mm outer diameter using advanced lens element manufacturing processes to provide the opportunity for rapid prototyping. Archer OpTx can deliver a guaranteed turn around in half the time typical in the industry.