- ホーム

- >

- OPIE'25

- >

- 展示会一覧

- >

- LAYERTEC GmbH

レーザーEXPO H-10

-

出展のみどころ

LAYERTEC is a leading manufacturer of high-precision laser optics with full in-house production—from raw glass to advanced coatings. Our expertise ensures superior quality, minimal rejection rates, full traceability via laser marking, and scalable solutions for R&D and OEM production.

-

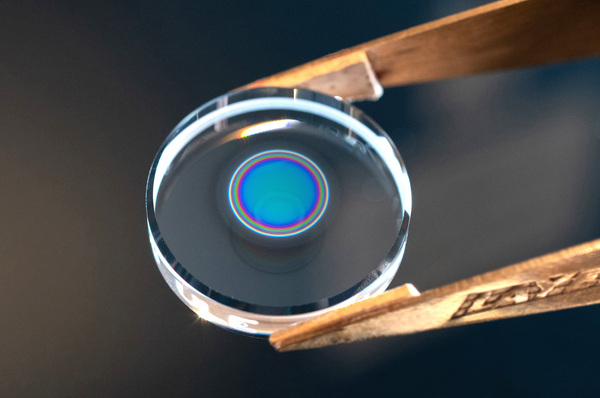

Chirped Mirrors with high LIDT and GDD Control

LAYERTEC designs custom chirped mirrors with adjustable phase response from 200 to 5000 nm, achieving GDD values as low as -10,000 fs². For optimal performance, we recommend chirped mirror pairs. We are currently developing -50,000 fs² GDD mirrors, available in limited quantities for R&D applications.

-

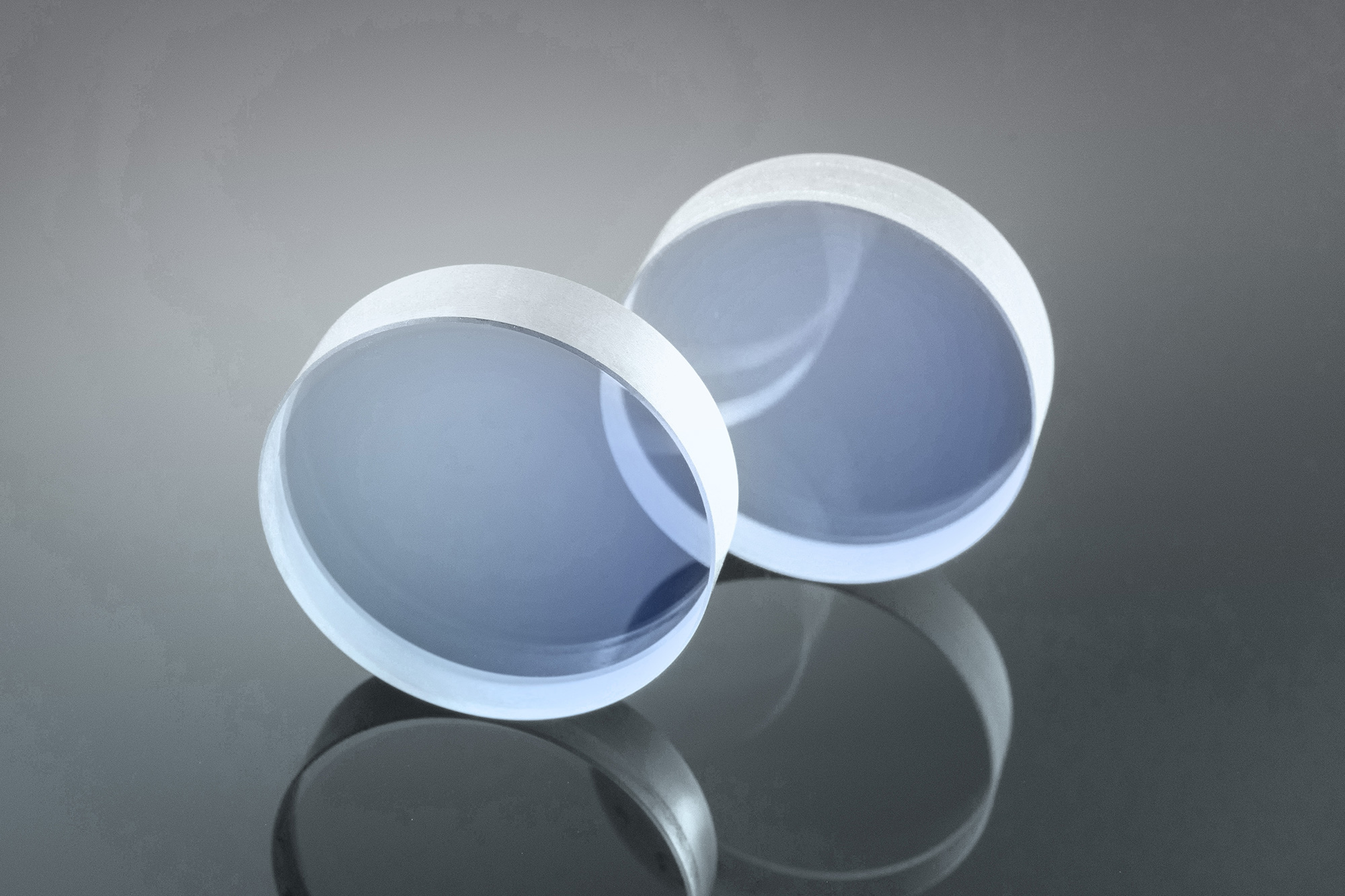

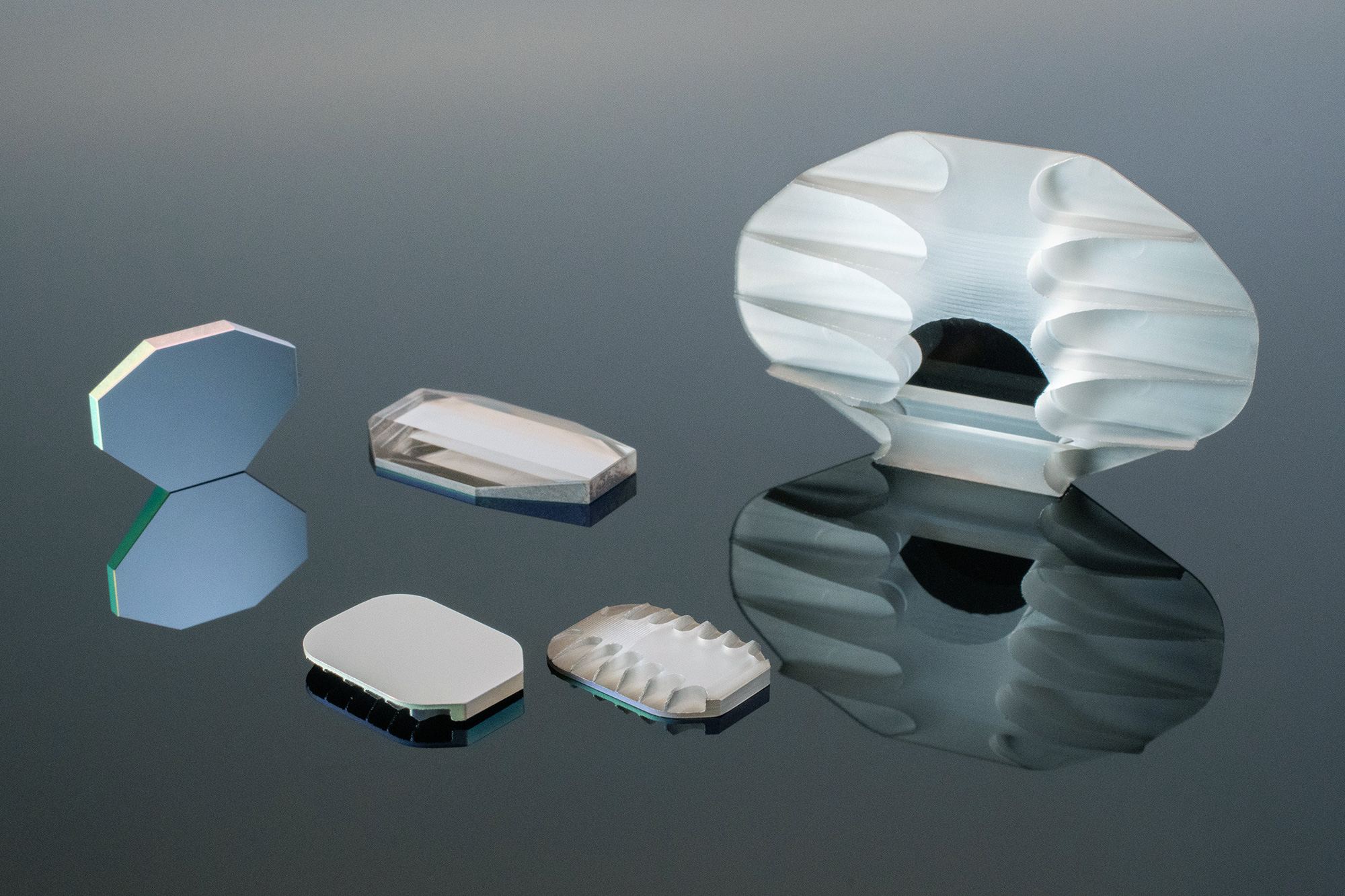

Lightweight Mirrors for Fast and Precise Laser Applications

LAYERTEC’s lightweight scanning mirrors feature an innovative leaf-like rear structure for fast, precise laser beam positioning. Their ultra-clean surfaces (low defect density) make them ideal for high-power laser applications.

-

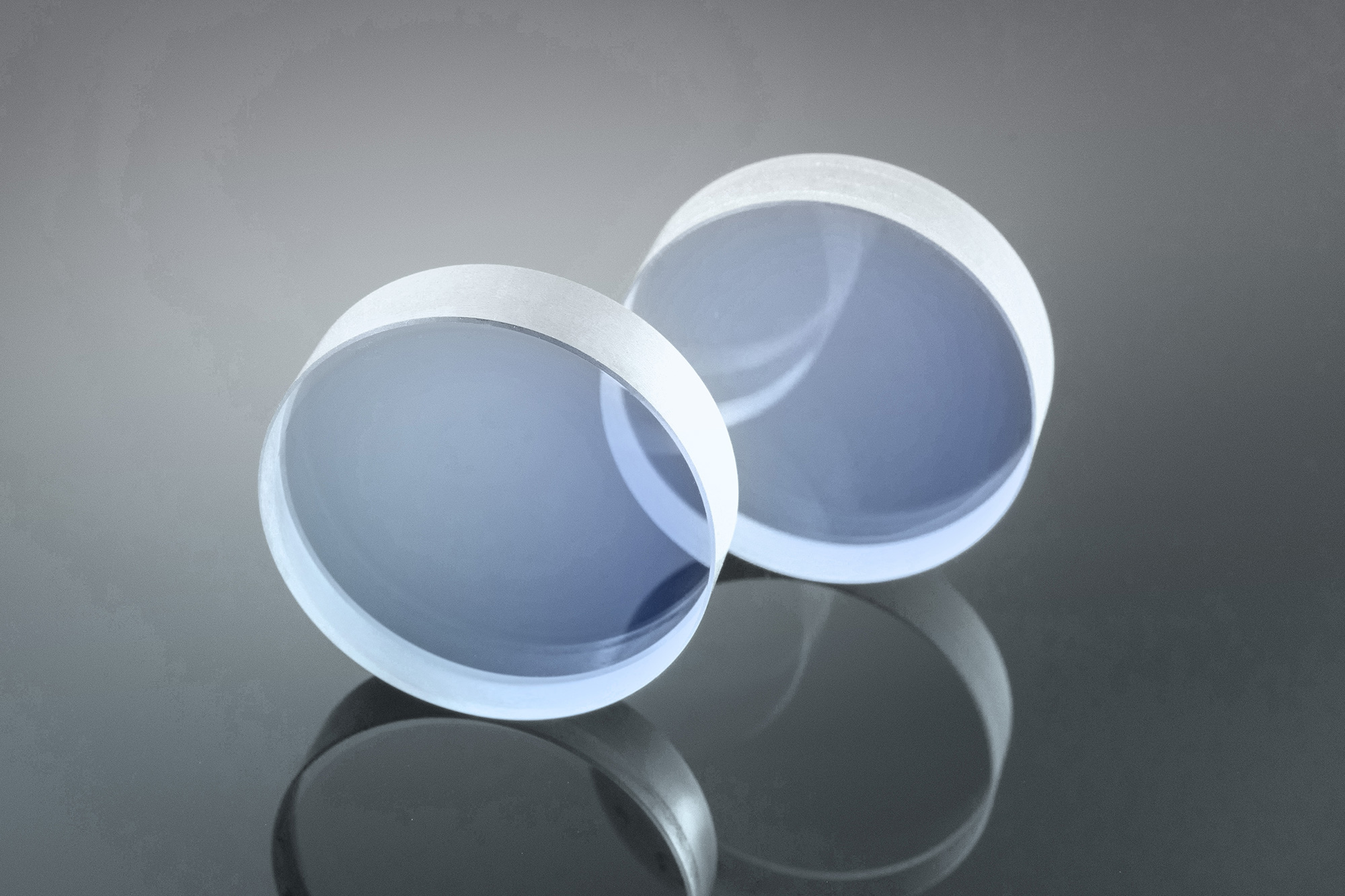

Low-Loss Optics - Minimal Absorption and Scattering Losses

LAYERTEC’s low-loss mirrors offer reflectivities above 99.999%, ensuring minimal absorption and scattered light losses. Achieving this requires exceptional substrate and coating quality. These mirrors are ideal for precise electromagnetic frequency measurements and CRD spectroscopy applications.

-

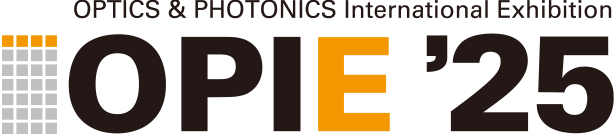

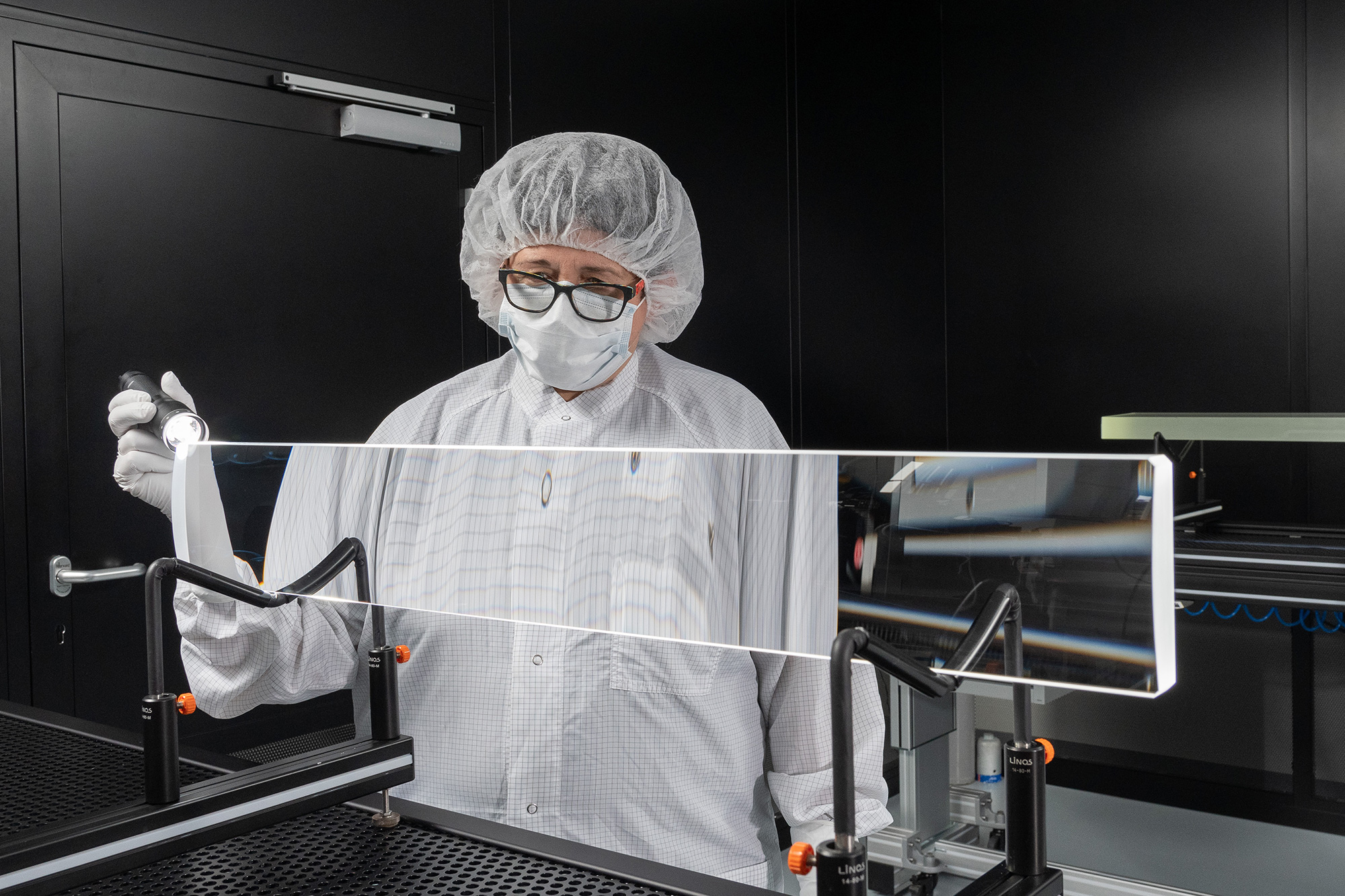

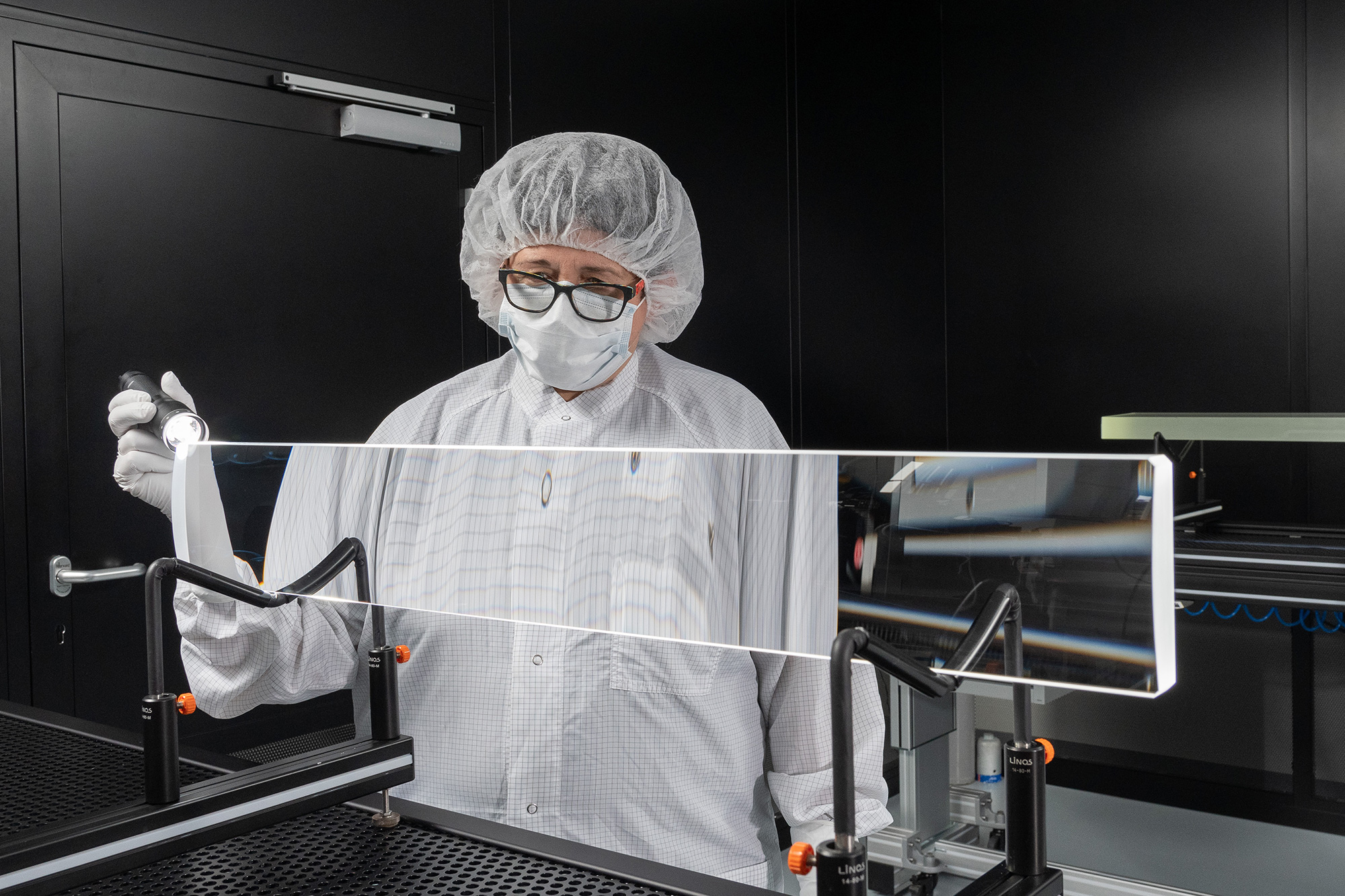

Large Optics up to 2000 mm

LAYERTEC manufactures high-precision optics up to 2000 mm in size, including flat, spherical, cylindrical, and aspherical shapes for both single and series production. Advanced metrology ensures precise optical parameters. We also provide high-performance coatings for UV to IR applications, optimized for optics up to 1000 mm.

-

Solderable Edge Coatings for Space Applications

LAYERTEC provides solderable edge coatings that enhance optical component durability in extreme space environments. These coatings ensure mechanical stability, precise alignment, and high optical performance under severe temperature variations. They are essential for environmental and climate satellites using high-power laser systems.

-

Assemblies

LAYERTEC offers advanced optical assemblies with broader spectral ranges and exceptional functionalities. The in-house joining techniques, like adhesive bonding or optical contacting, meet diverse customer demands. These techniques enable the manufacturing of assemblies with demanding alignment tolerances, providing mechanical strength and long-term stability even in challenging conditions.

-

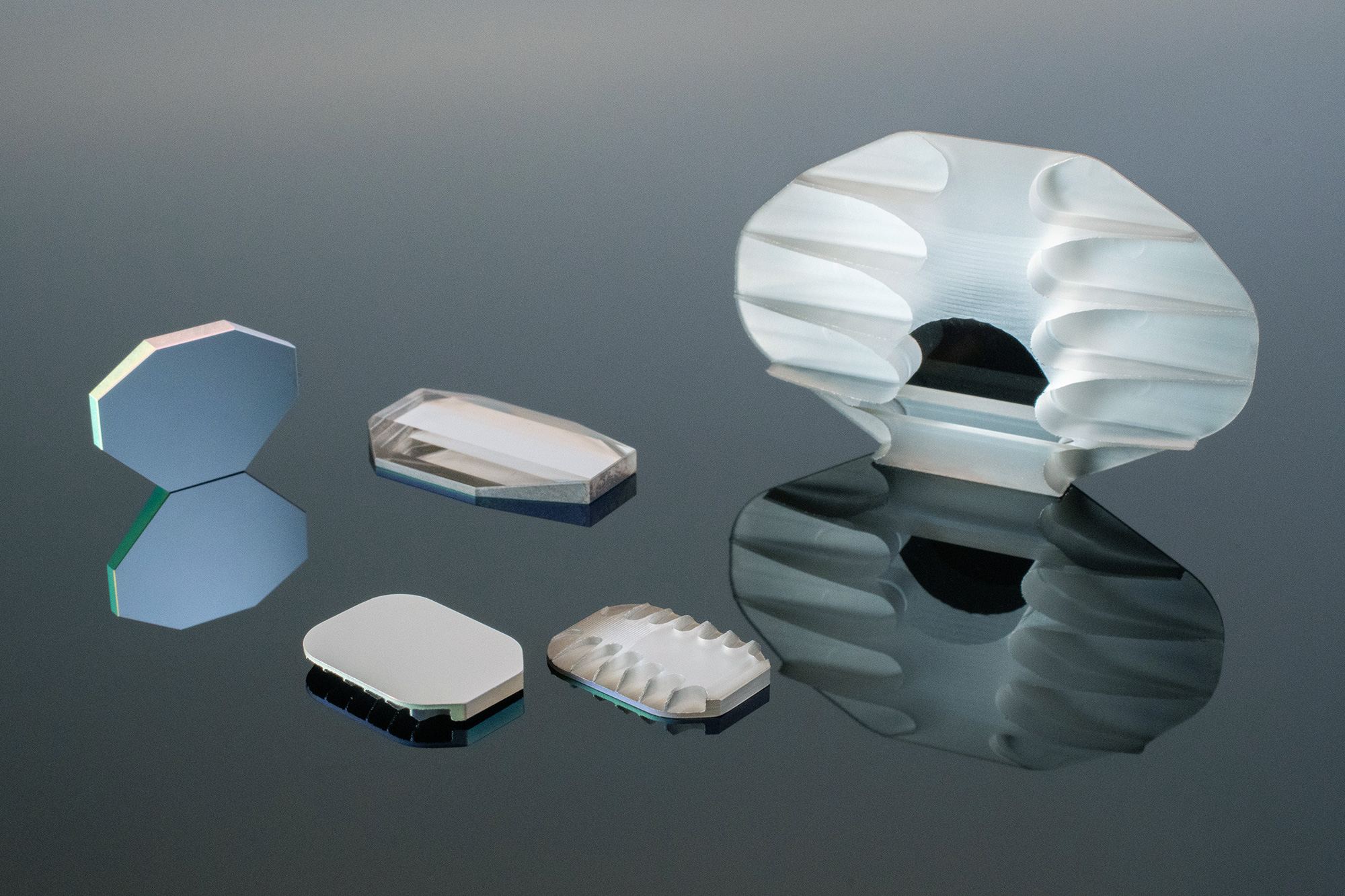

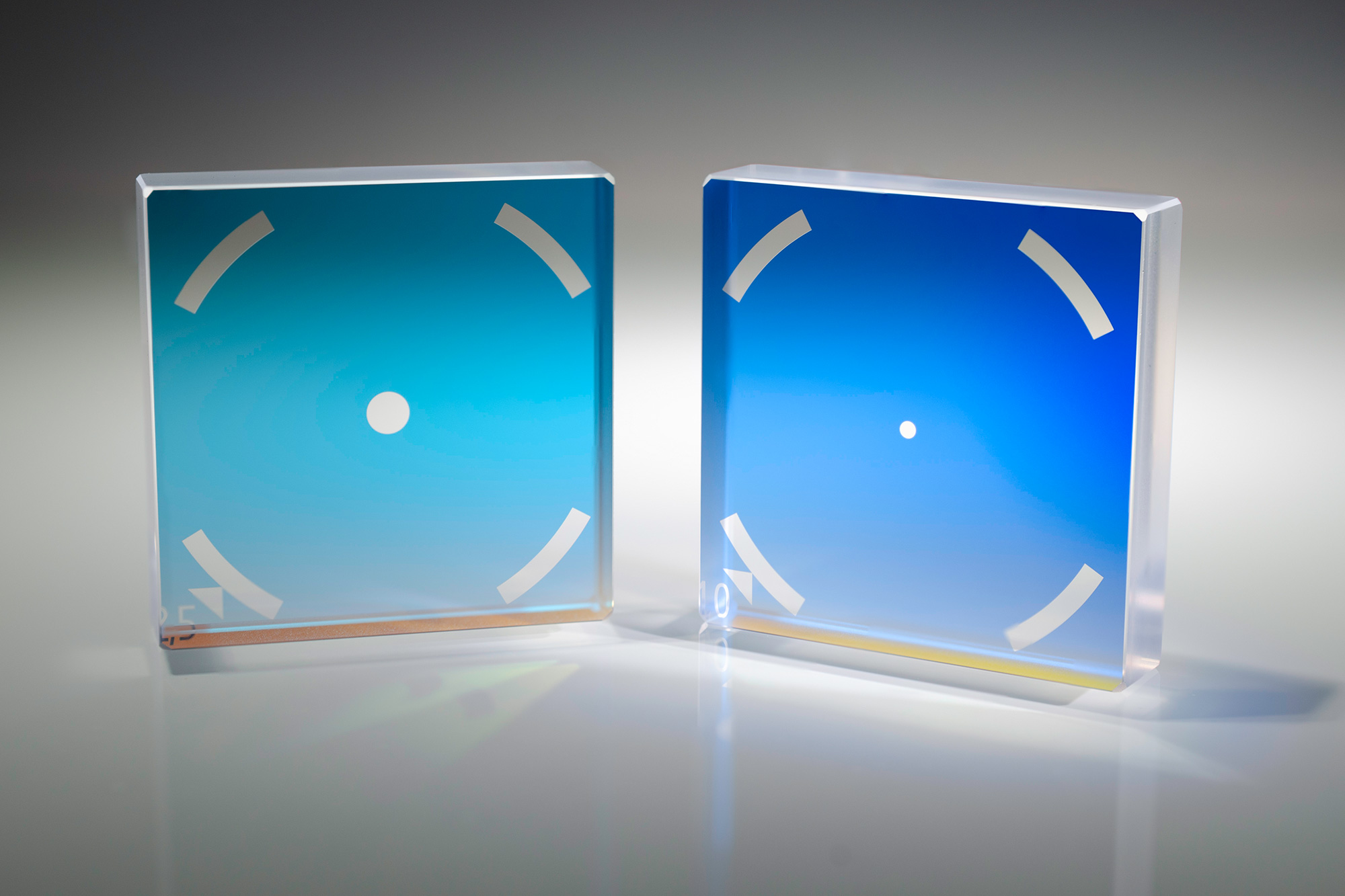

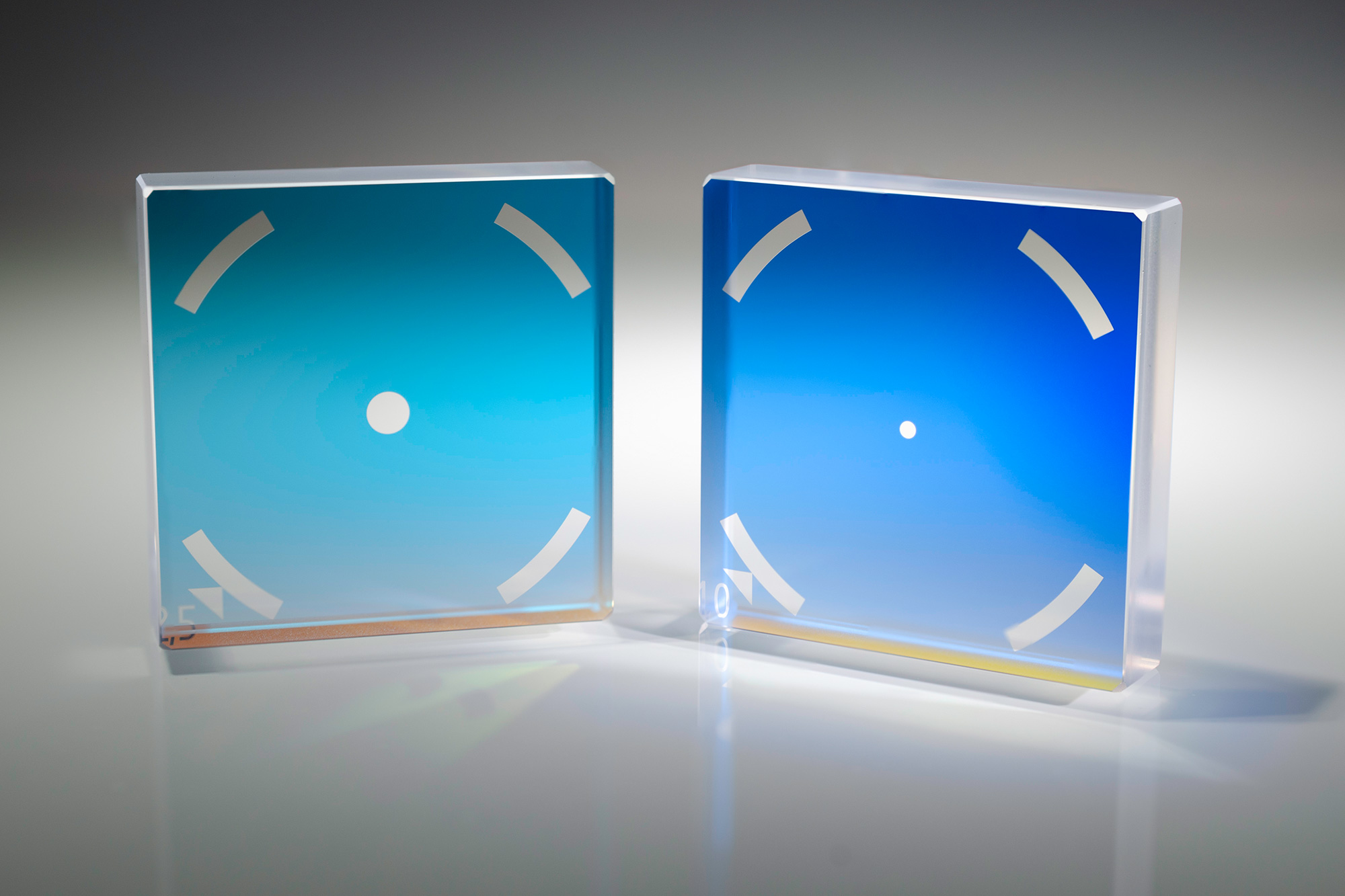

Lithographically Structured Layers

LAYERTEC offers optical coatings for specific applications. Different coating systems can be combined on a single surface. Mechanical masking is the simplest option, leaving parts of the surface uncoated. Segmented components enable lateral phase/amplitude modulation, mode selection and beam splitting. Structured components are laser-resistant and suitable for high-power laser systems.

-

High-Power Mirros

LAYERTEC provides mirrors for extreme power densities in continuous wave (cw) and pulsed laser applications. Featuring advanced coatings with minimal optical losses, they ensure high reflectivity and durability. Ideal for high-finesse cavities, these mirrors offer excellent performance and stability, meeting the stringent demands of industrial and scientific laser systems.

-

出展のみどころ

LAYERTEC is a leading manufacturer of high-precision laser optics with full in-house production—from raw glass to advanced coatings. Our expertise ensures superior quality, minimal rejection rates, full traceability via laser marking, and scalable solutions for R&D and OEM production.

-

Chirped Mirrors with high LIDT and GDD Control

LAYERTEC designs custom chirped mirrors with adjustable phase response from 200 to 5000 nm, achieving GDD values as low as -10,000 fs². For optimal performance, we recommend chirped mirror pairs. We are currently developing -50,000 fs² GDD mirrors, available in limited quantities for R&D applications.

-

Lightweight Mirrors for Fast and Precise Laser Applications

LAYERTEC’s lightweight scanning mirrors feature an innovative leaf-like rear structure for fast, precise laser beam positioning. Their ultra-clean surfaces (low defect density) make them ideal for high-power laser applications.

-

Low-Loss Optics - Minimal Absorption and Scattering Losses

LAYERTEC’s low-loss mirrors offer reflectivities above 99.999%, ensuring minimal absorption and scattered light losses. Achieving this requires exceptional substrate and coating quality. These mirrors are ideal for precise electromagnetic frequency measurements and CRD spectroscopy applications.

-

Large Optics up to 2000 mm

LAYERTEC manufactures high-precision optics up to 2000 mm in size, including flat, spherical, cylindrical, and aspherical shapes for both single and series production. Advanced metrology ensures precise optical parameters. We also provide high-performance coatings for UV to IR applications, optimized for optics up to 1000 mm.

-

Solderable Edge Coatings for Space Applications

LAYERTEC provides solderable edge coatings that enhance optical component durability in extreme space environments. These coatings ensure mechanical stability, precise alignment, and high optical performance under severe temperature variations. They are essential for environmental and climate satellites using high-power laser systems.

-

Assemblies

LAYERTEC offers advanced optical assemblies with broader spectral ranges and exceptional functionalities. The in-house joining techniques, like adhesive bonding or optical contacting, meet diverse customer demands. These techniques enable the manufacturing of assemblies with demanding alignment tolerances, providing mechanical strength and long-term stability even in challenging conditions.

-

Lithographically Structured Layers

LAYERTEC offers optical coatings for specific applications. Different coating systems can be combined on a single surface. Mechanical masking is the simplest option, leaving parts of the surface uncoated. Segmented components enable lateral phase/amplitude modulation, mode selection and beam splitting. Structured components are laser-resistant and suitable for high-power laser systems.

-

High-Power Mirros

LAYERTEC provides mirrors for extreme power densities in continuous wave (cw) and pulsed laser applications. Featuring advanced coatings with minimal optical losses, they ensure high reflectivity and durability. Ideal for high-finesse cavities, these mirrors offer excellent performance and stability, meeting the stringent demands of industrial and scientific laser systems.

- 住所

- Ernst-Abbe-Weg 1, 99441 Mellingen, GERMANY

- ウェブサイトURL

- https://www.layertec.de/

- 担当

- Ting-Yen Lee