光通信・要素技術&応用EXPO B-10

-

出展のみどころ

ESTEE Technologies was established in 2009,which is a high-tech enterprise that specialized in R&D,manufacturing,sales of ESD products and providing ESD solutions. We have R&D centers in Germany, Shenzhen,Shanghai,Dongguan and Hunan with top international experts and team.

-

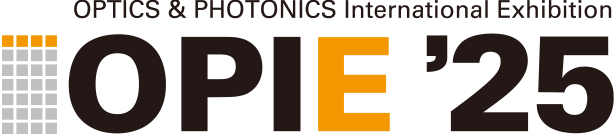

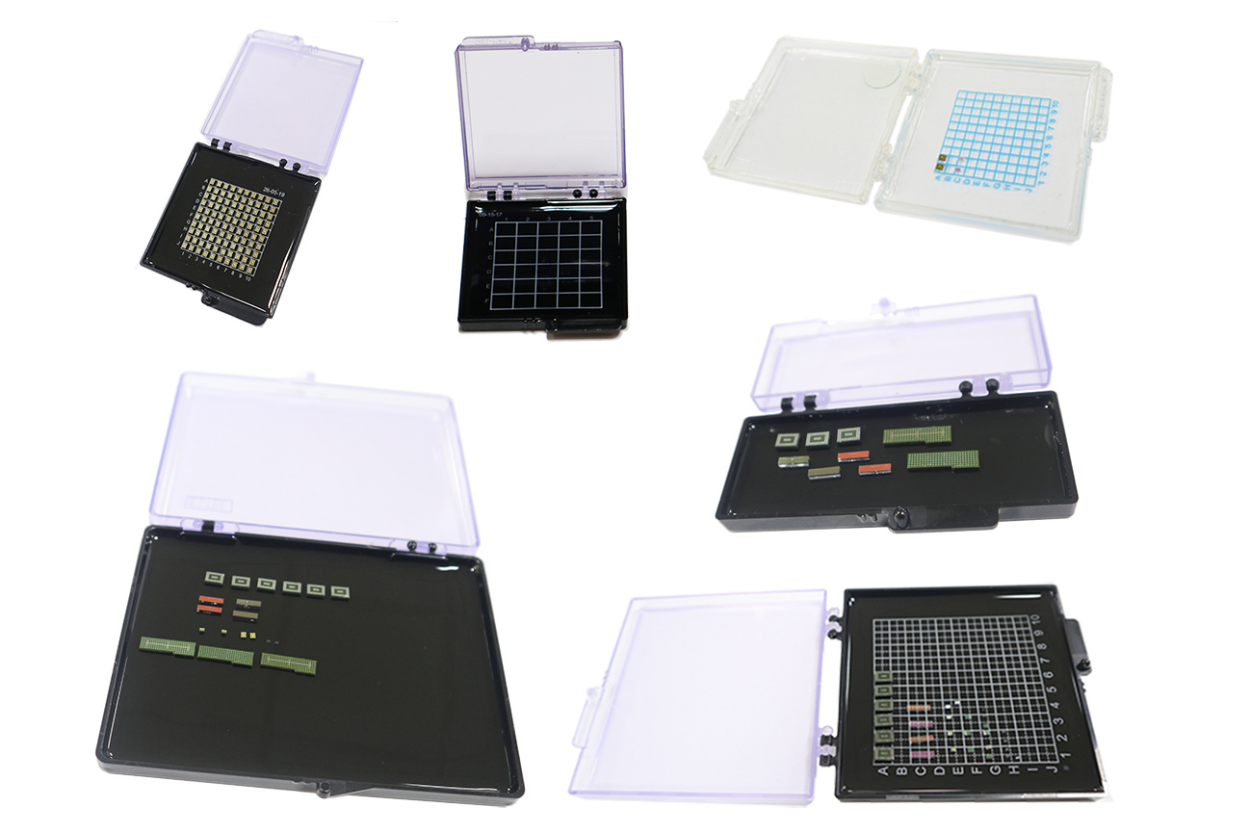

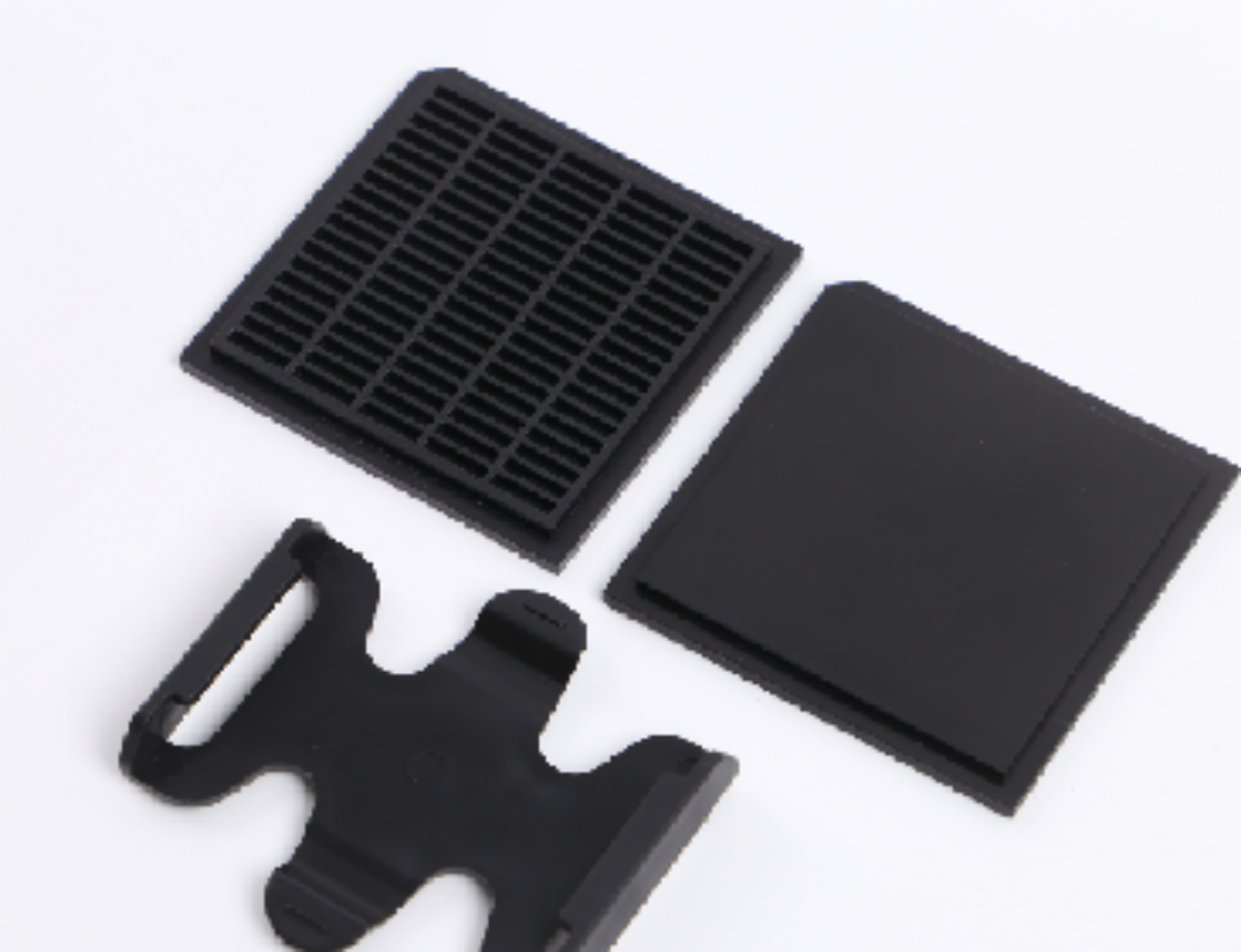

ESTEE-Box

ESTEE Gel-Box takes special macromolecule material with transparent colloid and the grid printed at the bottom of the colloid, which would not affect the viscosity of the surface. With excellent absorption, the Gel-boxes are applied to the storage and transportation of a series of high-tech products, such as optical mate

-

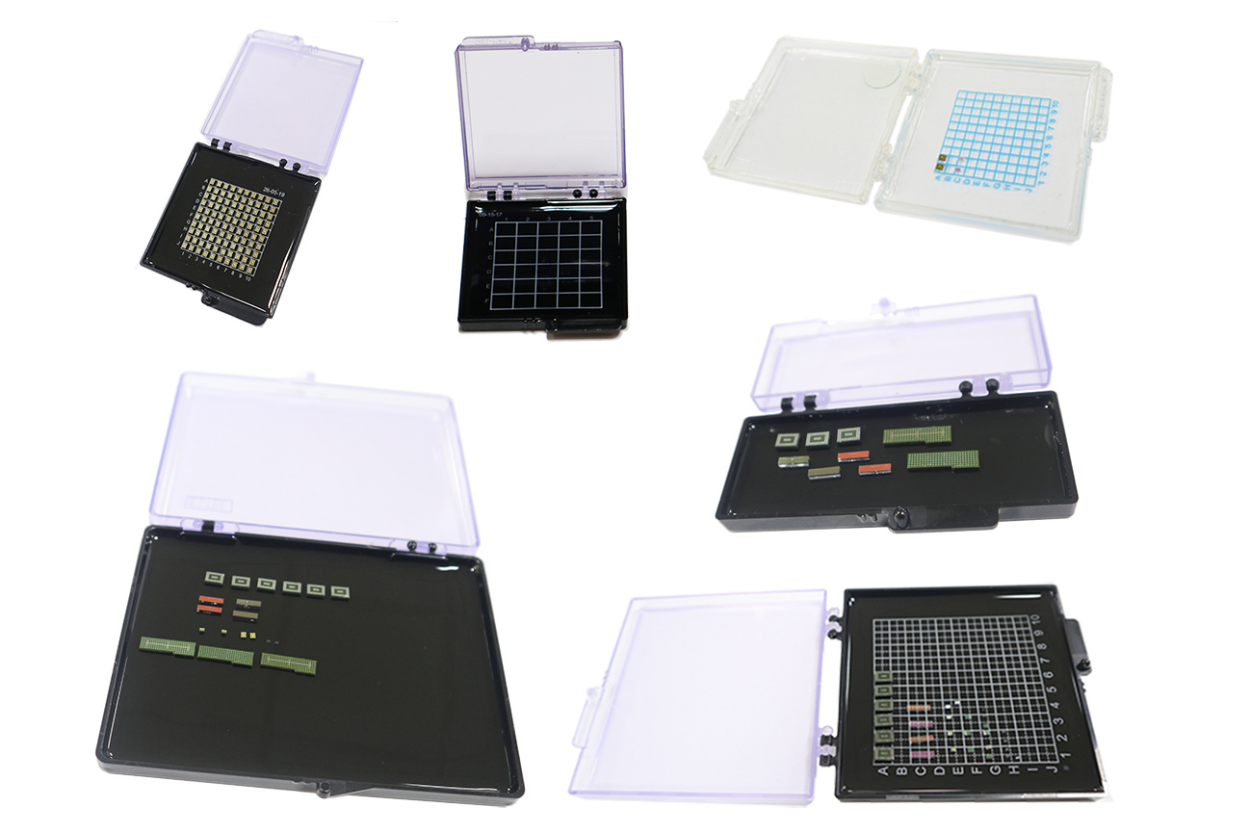

ESTEE-Tray

ESTEE-Tray is an anti-static non-silicon Tray (match with box), takes the special macromolecule material with transparent colloid and the grid printed at the bottom of the colloid, which would not affect the viscosity of the surface. It has the excellent absorption, and the lighter viscosity can ensure the absorption of automatic equipment.

-

ESTEE-VR

ESTEE-VR takes special macromolecule transparent film to assemble, normally the sheet attaches to tray strictly to ensure transportation safety. When implement to vacuum, the adhesion will be decreased rapidly for automatically place and pick.

-

ESTEE-NT

The ESTEE-NT series of wafer Pack products is named as Die. The series provide a safe and convenient way to package and transport optics and other microelectronic parts. They are a variety of sizes and materials for customers to choose. The injection mold has high precision, and the product size and flatness are accurate. The material is made of permanent anti-static material, which is in line with ESD and RoHs environmental protection labels.

-

UV Tape

ESTEE UV tape has high peel strength initially, and the viscosity will be decreased after UV irradiation. It also has good ductility and easily been peeled off. It has excellent anti-static performance on both sides and avoids static damage of IC paste.

-

QFN Tape

ESTEE QFN tape is widely used for pasting on the lead frame of the semiconductor and played a shielding function to prevent the penetration of the resin into the shielding area during the molding process. This product has excellent temperature resistance an anti-static performance.

-

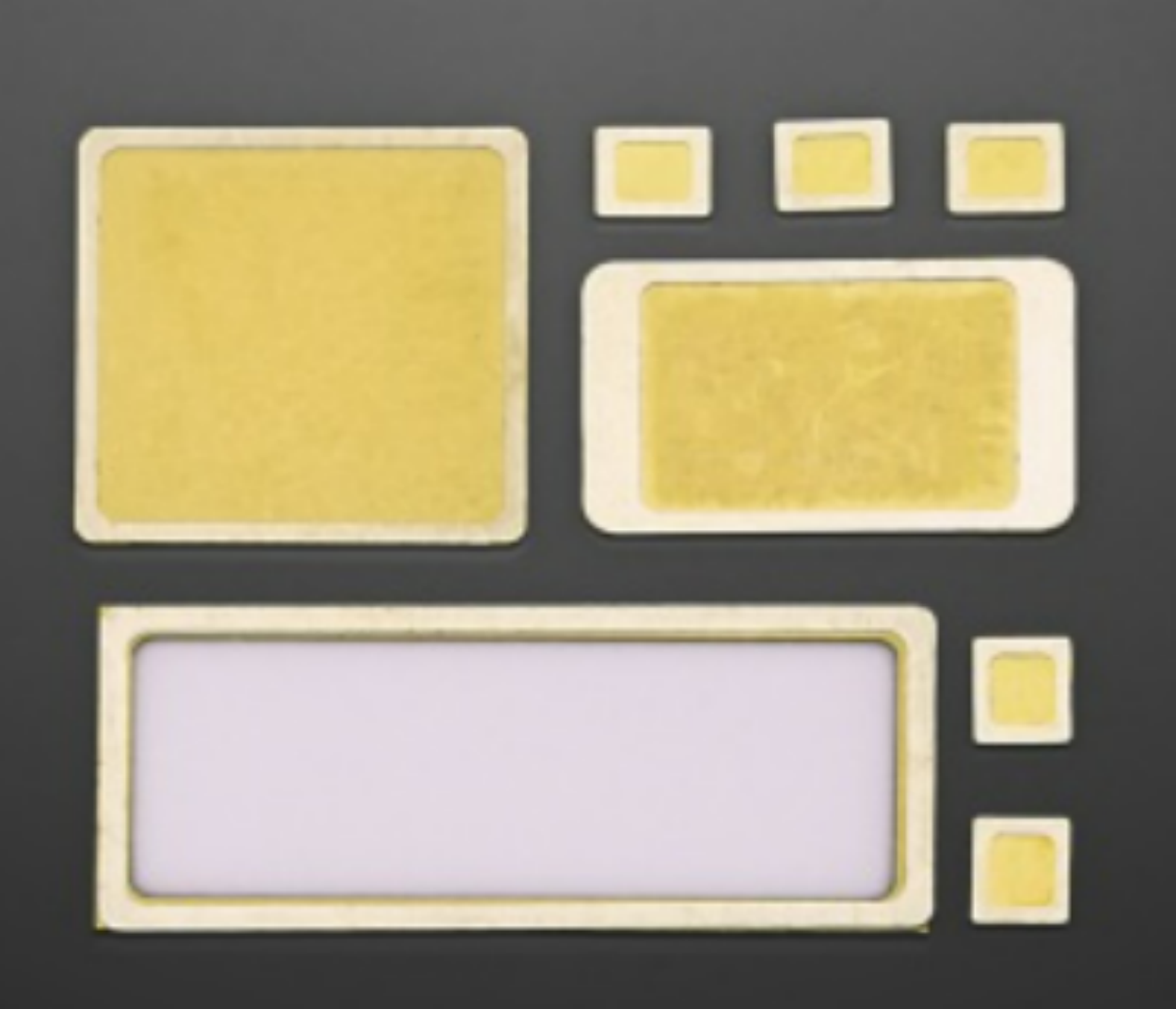

Preformed Solder Pad

In the electronic manufacturing industry, accurate solder quantity is crucial to ensure the strength of solder joints, and the mainstream trend of compact and miniaturization of electronic devices, how to ensure the strength of solder joints has become a challenging issue in the industry. Preformed solder can provide a solution to this very challenging problem and is widely used in the field of precision welding.

-

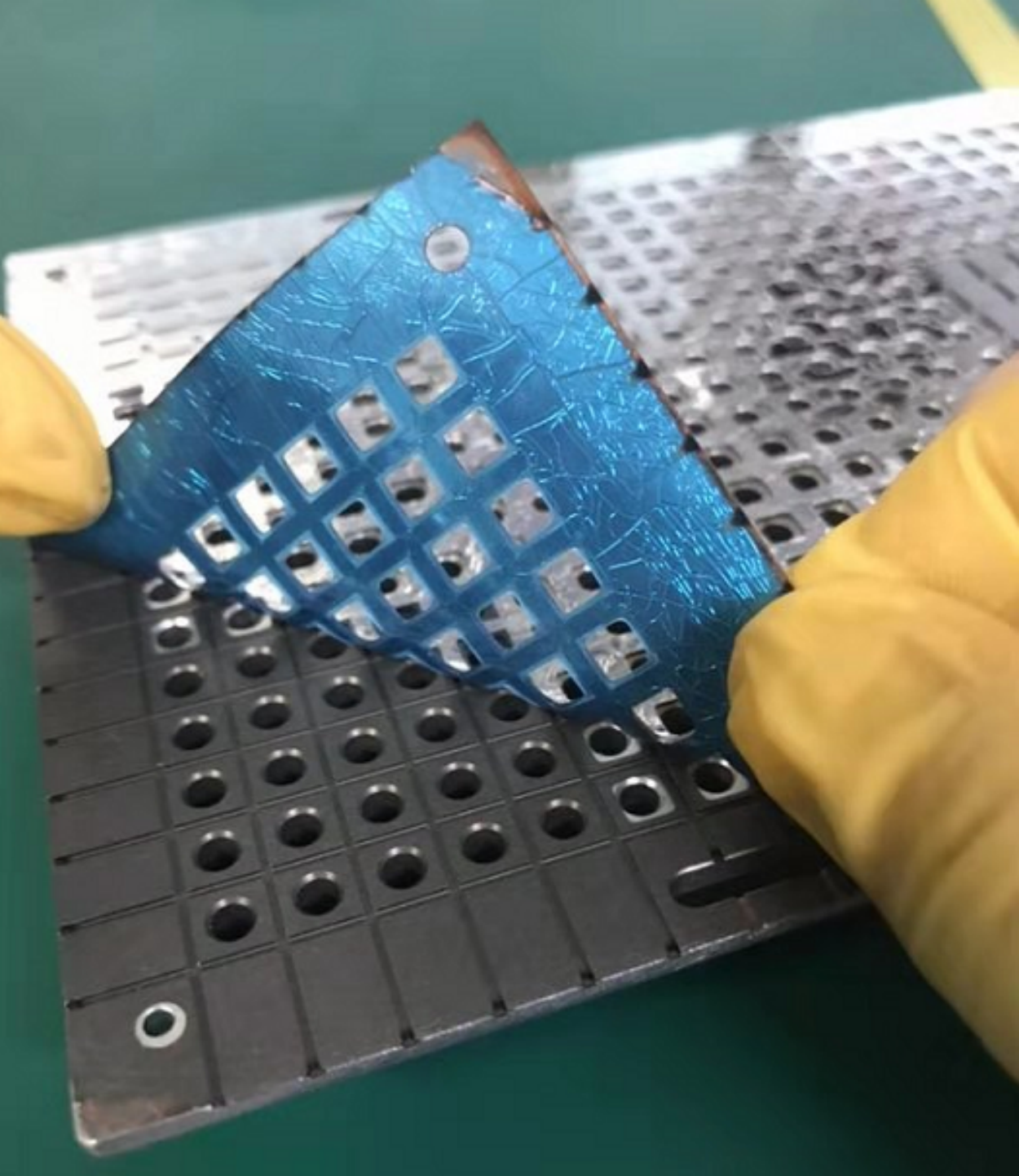

Sputter tape

SP609/613 series is a foam tape special for sputtering process, which is applied to high temp vacuum sputtering to fix IC、SIP module、BGA. This product has good viscosity, excellent anti-static performance and buffer performance, especially for LGA with in dots on the bottom,tin dots can be embedded in the glue for good protection. There is no over flow, no glue residue and the debris are under control after sputtering process.

-

出展のみどころ

ESTEE Technologies was established in 2009,which is a high-tech enterprise that specialized in R&D,manufacturing,sales of ESD products and providing ESD solutions. We have R&D centers in Germany, Shenzhen,Shanghai,Dongguan and Hunan with top international experts and team.

-

ESTEE-Box

ESTEE Gel-Box takes special macromolecule material with transparent colloid and the grid printed at the bottom of the colloid, which would not affect the viscosity of the surface. With excellent absorption, the Gel-boxes are applied to the storage and transportation of a series of high-tech products, such as optical mate

-

ESTEE-Tray

ESTEE-Tray is an anti-static non-silicon Tray (match with box), takes the special macromolecule material with transparent colloid and the grid printed at the bottom of the colloid, which would not affect the viscosity of the surface. It has the excellent absorption, and the lighter viscosity can ensure the absorption of automatic equipment.

-

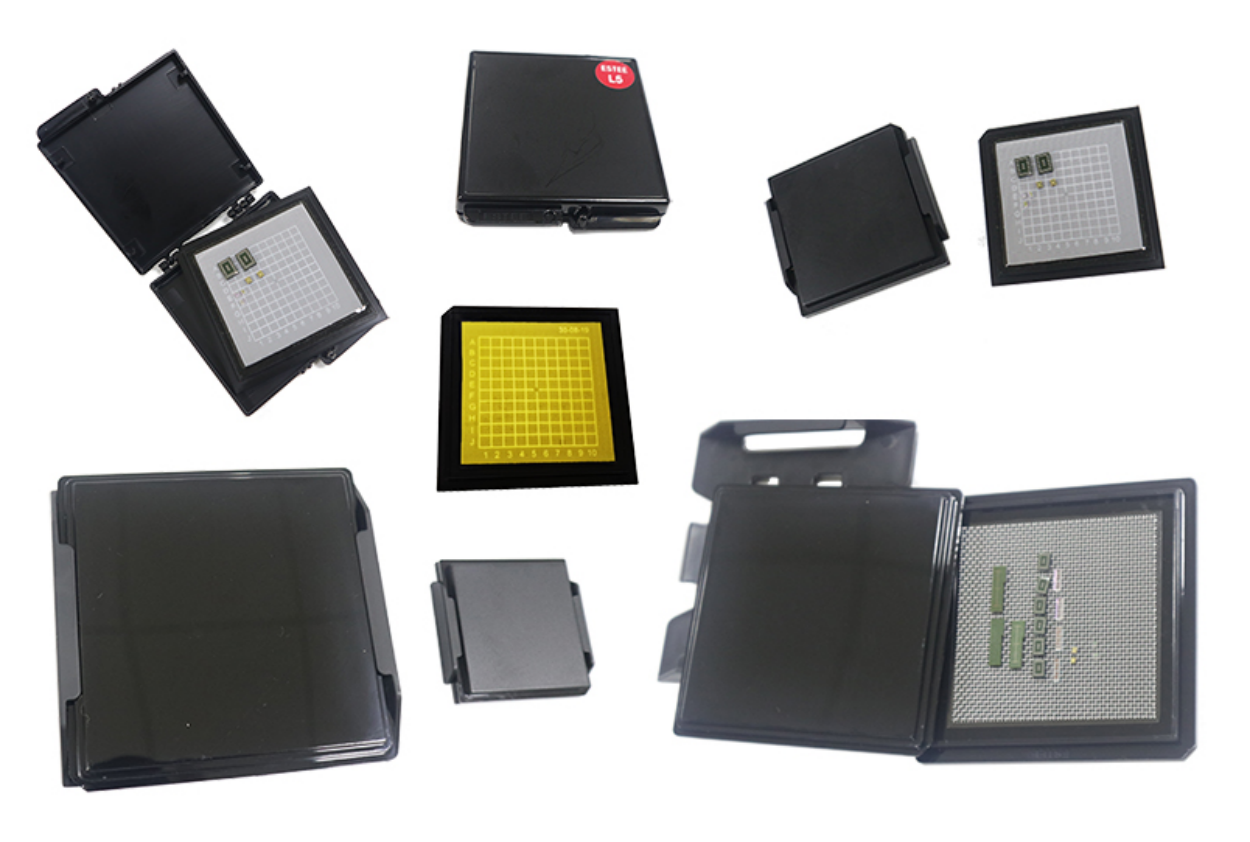

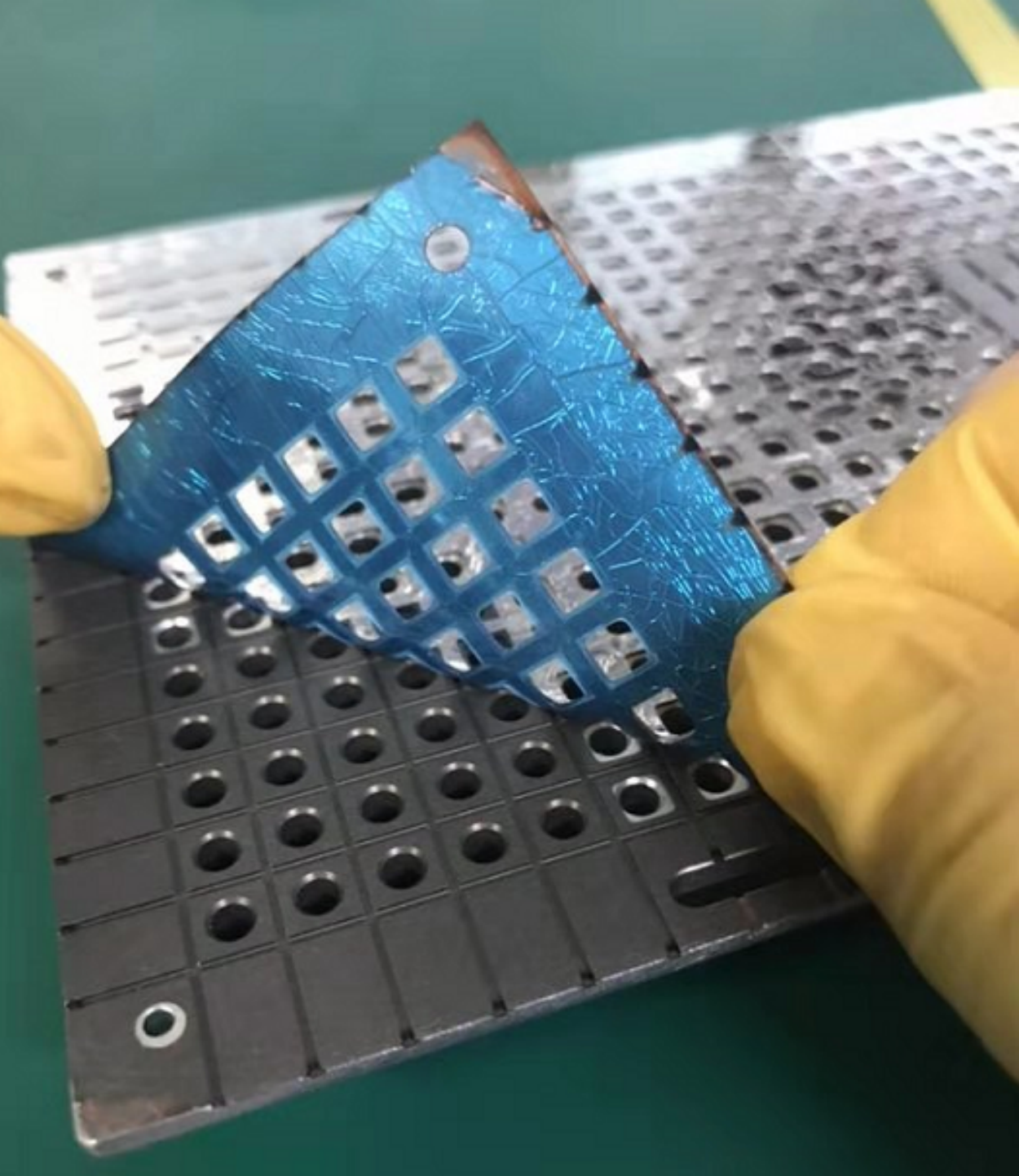

ESTEE-VR

ESTEE-VR takes special macromolecule transparent film to assemble, normally the sheet attaches to tray strictly to ensure transportation safety. When implement to vacuum, the adhesion will be decreased rapidly for automatically place and pick.

-

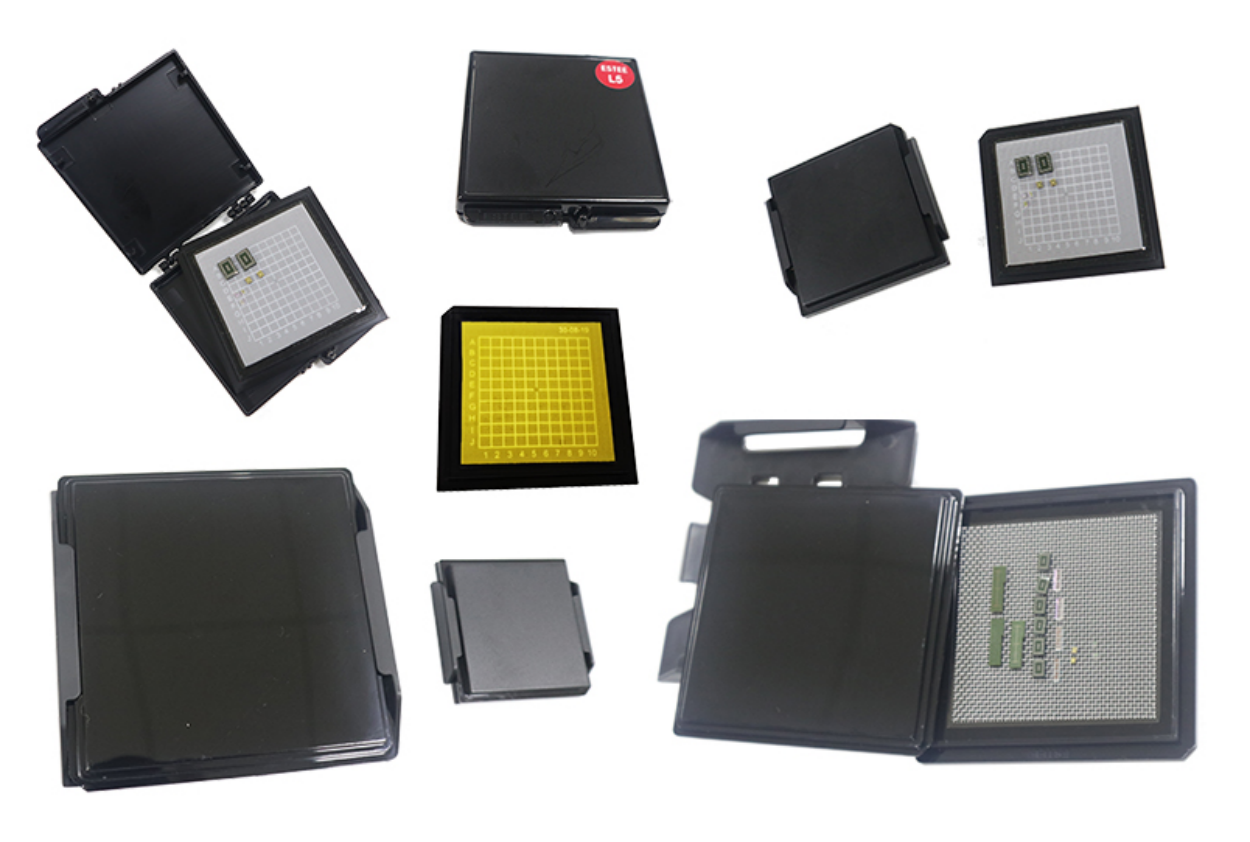

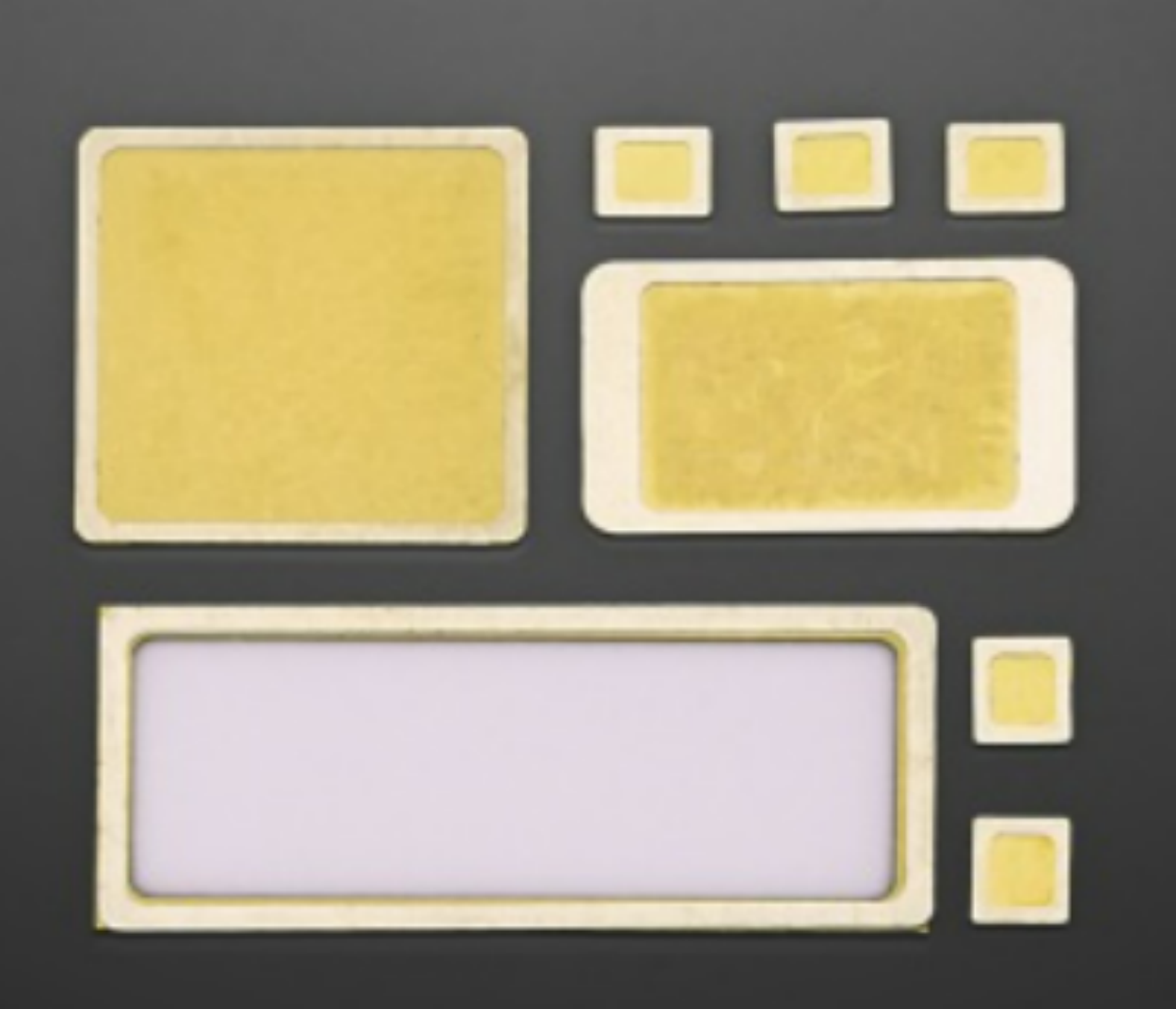

ESTEE-NT

The ESTEE-NT series of wafer Pack products is named as Die. The series provide a safe and convenient way to package and transport optics and other microelectronic parts. They are a variety of sizes and materials for customers to choose. The injection mold has high precision, and the product size and flatness are accurate. The material is made of permanent anti-static material, which is in line with ESD and RoHs environmental protection labels.

-

UV Tape

ESTEE UV tape has high peel strength initially, and the viscosity will be decreased after UV irradiation. It also has good ductility and easily been peeled off. It has excellent anti-static performance on both sides and avoids static damage of IC paste.

-

QFN Tape

ESTEE QFN tape is widely used for pasting on the lead frame of the semiconductor and played a shielding function to prevent the penetration of the resin into the shielding area during the molding process. This product has excellent temperature resistance an anti-static performance.

-

Preformed Solder Pad

In the electronic manufacturing industry, accurate solder quantity is crucial to ensure the strength of solder joints, and the mainstream trend of compact and miniaturization of electronic devices, how to ensure the strength of solder joints has become a challenging issue in the industry. Preformed solder can provide a solution to this very challenging problem and is widely used in the field of precision welding.

-

Sputter tape

SP609/613 series is a foam tape special for sputtering process, which is applied to high temp vacuum sputtering to fix IC、SIP module、BGA. This product has good viscosity, excellent anti-static performance and buffer performance, especially for LGA with in dots on the bottom,tin dots can be embedded in the glue for good protection. There is no over flow, no glue residue and the debris are under control after sputtering process.

- 住所

- Southwest corner at the intersection of West Lianbin Street and Nanyang Road, Louxing District, Loudi City, Hunan Province.

- ウェブサイトURL

- http://www.esteecn.com

- 担当

- Xuehong Zeng 曾雪红